BRANCH FACTORY OF EPS CEMENT SANDWICH PANEL

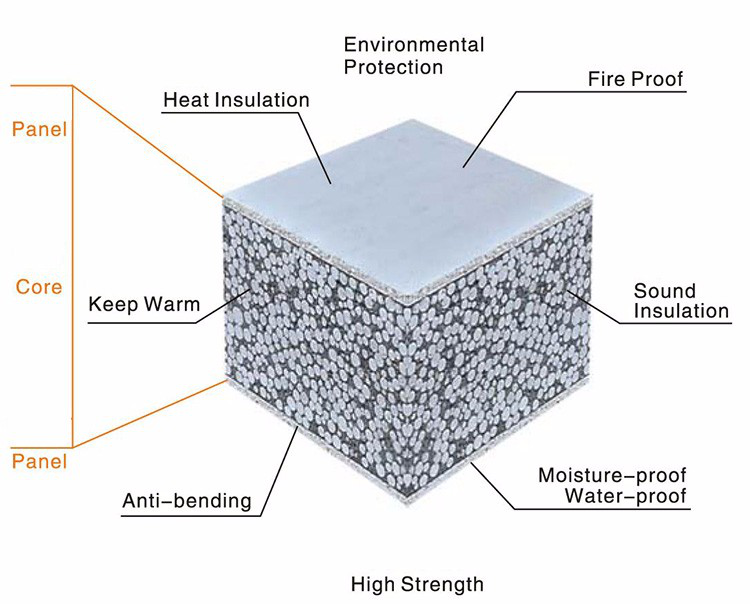

Brief introduction of EPS cement sandwich panel:

Kingway EPS cement sandwich panel is kind of light weight energy saving wall material with reinforced calcium silicate board as surface panel,cement, EPS, fly ash as core material and forming by one time compound. It has features of light weight, high intensity, thin,waterproof and fire proof,heat preservation,

sound insulation, quakeproof, low cost and space-saving. Eps cement sandwich panel is widely applied to interior wall partition, exterior wall and roof for all kind of constructions. Its birth marks the wall material will appear renewal trend,instead of traditional block, the new architectural thoughts and its outstanding performance can meet the requirements of modern architectural environment.

Main Advantages:

1.Heat Preservation:Major material is antifreezing,heat preserving and environmental friendly.

2.Heat Insulation:Adjust the indoor temperature at a constant range.

3.Fire-proof:4.5mm calcium silicateboard is fireproof,Eps & Cement sandwich panel can be against a high temperature for 4 hours.

4.Water-proof: Experiment has proved that water pool can be made by Eps and Cement sandwich panel without absorbing any water and no

leakage at all after one year.

Products:

Installation

1.Set line: Set line and carry panel in position

2.Saw panel: Use hand-hold electric saw to cut freely

3.Sizing: Sizing cement on tenon side of two panels then spread polymer mortar on one tenon

4.Installation: Carry panel prepared to be installed panel

5.Plant bar in wall and pillar: Drill one hole in the original pillar or wall and fix panel by one steel bar.

6.Correct and fix: Use one guiding ruler to check and level correction.

7.Plant bar in structure beam: Drill one hole in structure beam and plant one reversed 7 type shaped steel bar to fix with wall panel.

8.Plant bar in floor: Drill one hole in floor and plant 7 types shaped steel bar to fix with wall panel.

9.Plant bar between wall panel: Plant one 200mm length steel bar in the angle of 45 degree to fix between two panels.

10.Install electric wire and switch: Set lines on the place required to be setted with concealed wire and switch box.

11.Grout and fill slurry: Fill and handle corrected wall panel with polymer mortar.

12.Scrapping ash and sticking anti-crack cloth, coating: Stick anti-crack cloth and brush coating after grouting slurry.

Hanging heavies such as water heater

EPS cement sandwich panels match with steel structure

Construction cases in East-south Asie

1.Product Description

Thickness | length | Width | Shipping method |

60mm | 2440mm/2200mm | 610mm | 780sqm/40 GP |

75mm | 2440mm/2200mm | 610mm | 630sqm/40 GP |

90mm | 2440mm/2200mm | 610mm | 525sqm/40 GP |

100mm | 2440mm/2200mm | 610mm | 460sqm/40 GP |

120mm | 2440mm/2200mm | 610mm | 400sqm/40 GP |

150mm | 2440mm/2200mm | 610mm | 300sqm/40 GP |

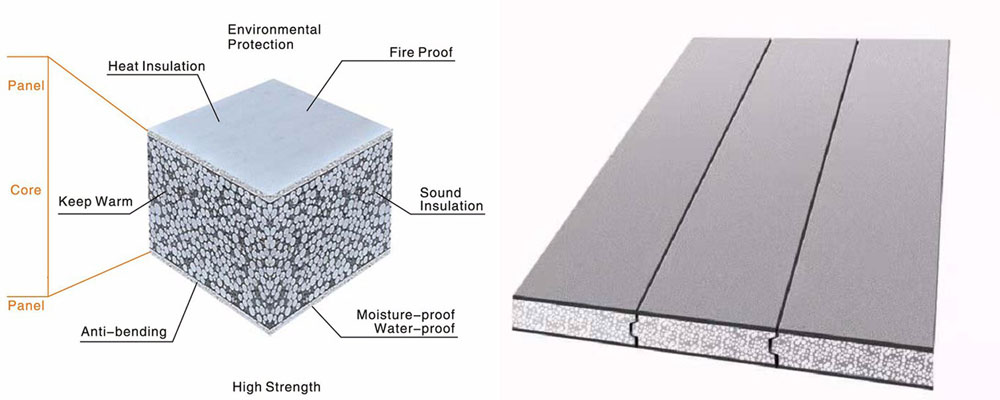

Production of EPS Cement Sandwich Panel which uses calcium silicate board as both sides surface panel,expanded polystyrene,ceramsite,cement, and other additives as fillings materials inside.As above and following lists,you can find the normal specifications and performance:

Workshops

Products Name: | Low cost Prefab House EPS Cement Sandwich Panel |

Double Sides Surface Board: | Calcium silicate board 5.0mm thickness; Fiber reinforced cement board |

Core: (100% non-asbestos) | EPS beads, Patented additive Portland cement, sand |

Panel Joining Method: | Tongue & Groove Type |

Specification: (Length*Width*Thickness)

| 2440/2400/2270/2200mm*610mm *Regular thickness 60/75/90/100mm

|

|

|

Pallet packing and container loading |

|

Our Certificates:

CE, ISO9001, ISO14000, SGS, STC, BV, National Test, Patent acquired