AAC (ALC) Panel

·200,000 square meters comprising the departments of production, quality control, maintenance, inventory, management and R&D.

· Staff made up of 80 collaborators with the highest professional training.

· Annual production capacity:

·300,000 cubic meters of AAC reinforced panels.

·600,000 cubic meters of AAC blocks

·100,000 tons of specialty mortars.

OUR WORKSHOPS OF ALC PANEL

OUR VIP CUSTOMERS VISIT OUR FACTORY

Certificates

Kingway always adheres to the concept of "scientific management, courageous innovation", continuously improves management, and wholeheartedly provides superior products and services to its customers.

1. In 2012, it was entitled as a "High and New Technology Enterprise".

2. In 2012, the production base of Kingway ALC panels was appraised as part of the "2012 Resource Conservation and Environmental Protection Projects" by the National Development and Reform Commission.

3. In 2012, "Sunbeach" won a title of "Brand-name Product of Shandong Province".

4. In 2012, the company has passed the certification of ISO9000 Quality Management System and ISO14000 Environmental Management System.

5. In March 2013,it has cooperated some austrlian customers to get the CodeMark certification for Australia & New Zealand.

6. In July 2013, it passed the SGS certification ("Audited Supplier" issued by SGS and Made-in-china.com).

7. In Oct. 2013, it has cooperated with some customers to get the BS certification in Singapore.

8.In july 2017,it has got the CE certificate for AAC(ALC)PANEL BLOCK

9.In 2018,it has got the SGS test reports for Fireproof,Acoustic and MADS green materials of ALC panels

10. We have been golden supplier in Alibaba.com for 12years (https://qdkingway.en.alibaba.com/)

INTRODUCTIONS FOR ALC PANEL

Water-proof Panel

AAC panel of high strength can hang heavy objects

AAC panel technical index

Note: Testing index uses AAC internal and external wall panel as sample. It can be adjusted according to different customer’s requirements. It’s suitable for both structural and non-structural application.

Internal Wall Panel  | |

|  |

It also can be used for outsourcing fire panel of steel beam and columns, and the veneer and the external wall insulation panel. | |

| |

AAC panel is processed according to the definitized sizes by actual field measurement. As a prefabricated product, it's of high precision, sawable and drillable. Used in dry operation, it is convenient to install in a simple process, greatly shortening the construction period, and improving the efficiency and quality of construction. The reinforcement (reinforcing bar) is calculated and determined according to the work load, the specifications of the panel, and the Applications Handbook of AAC panel; Kingway provides typesetting, the number of node design and engineering required specifications sheet. | |

| |

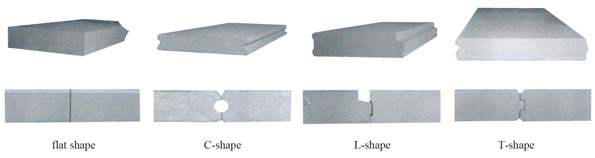

Specifications:Width: 600mm; | |

External Wall Panel

AAC panels can be used directly in exterior walls of concrete structures and steel structures. As an excellent heat insulator, they surpass most other similar building materials. They are also a guarantee of a comfortable and pleasant environment inside the buildings, with lower heating and cooling costs throughout the lifespan of a building.

AAC panels improve the reliability and security of node strength in external walls. During the rotation and extension in plane of the connecting nodes of wallpanels, AAC panels ensure that the walls can be adapted to the interlayer displacement in different directions of the main structure, and satisfies the need for the interlayer deformation of the main structure conforming to the seismic design intensity.

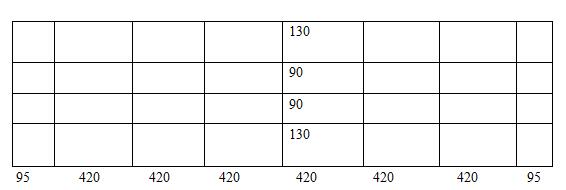

The installation node of AAC external panels is scientifically designed, with high strength and a certain amount of rotating performance. It can bear an interlayer displacement of between 1/200 to 1/50 without damage or only a minor damage. AAC panels are regarded as constructional elements with flexible connection in terms of seismic design, so their stiffness and seismic bearing capacity are not counted. Structure members supporting the AAC external panels can count the effect of seismic action of AAC wall panel as an additional effect, and meet the anchoring requirement of connecting accessories. Specifications (UNIT:mm)

|

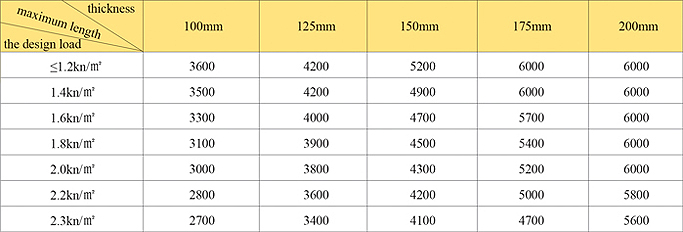

Floor Panel

AAC floor panels, with a scientific reinforcement design scheme and raw materials proportion during production, ensures excellent bearing capacity and combination properties of good bearing and thermal insulation. With light weight, good overall performance and small inertia force in earthquake, AAC floor panels give the buildings a good anti-seismic capacity, and are applicable in the buildings of earthquake-prone areas .

|

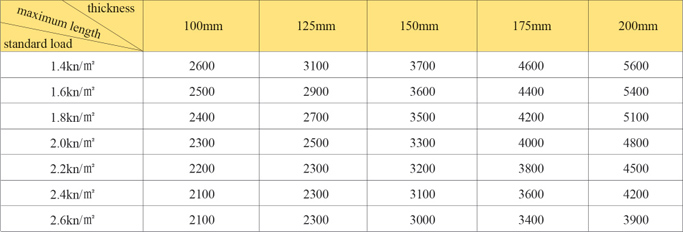

Roof Panel

AAC roof panels are of light weight, being only 1/3 of ordinary reinforced concrete prestressed hollow slabs, so 5-6 pieces of panels can be hoisted at one time in the construction. Furthermore, asphalt felt waterproof coiled material can be directly laid in roof, thus avoiding wet operations, speeding up the construction progress and shortening the construction period. AAC roof panel roofs should use slope structure, instead of mortar or other materials, for the building to find the slope. After the complete installation of AAC roof panels, waterproofing membranes can be directly adhered, or can be pasted after a thin layer of polymer mortar is made.

For specifications and standard designs of Floor panels and Roof panels, please refer to this following list. Relevant reinforcement is to be designed according to the specific design load and standard load.

Specifications and Standard Designs (UNIT:mm)

the standard load = the standard load value of the surface layer of building other than weight and standard value of live loads on roof |

SPECIAL 75MM AND 50MM PANEL

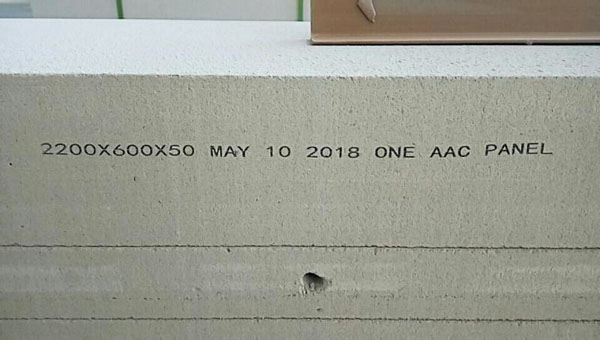

Kingway has produced and exported the special 75mm and 50mm panels for Austalia and New Zealand for more than 10years,it can produce 75mm panel with double layers or single layer of reinforcing bar,50mm panel of single layer of reinforcing bar,it has cooperated many big customers such as “Knauf Compleo”“ATBS Maxiwall”“One AAC”etc. to get the CodeMark certificate,pls kindly check our company’s name “ Qingdao Kingway Construction Co.,Ltd.” from the import system files of australian Customs.

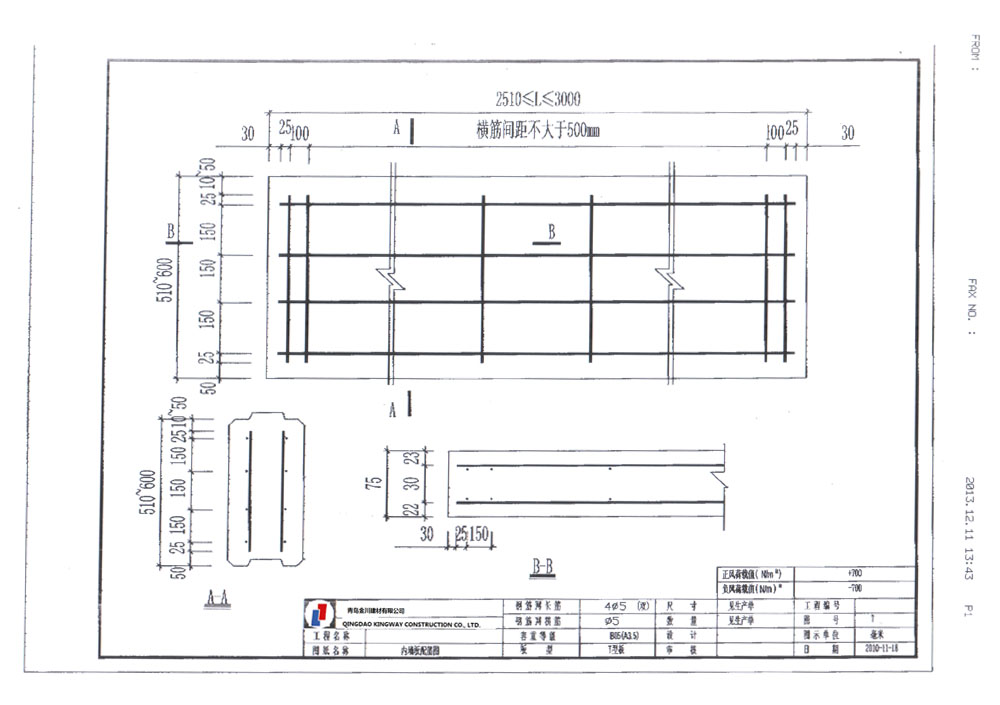

DOUBLE LAYERS OF INSIDE BARS FOR 75MM PANEL

75mm panels

Single layer of reinforcement bar of 50mm panel

Unit:mm

Panel:Thickness 75mm and 50mm,Singel layer of reinforcement

Reinforcement bars:Long bar 5x5Φ(diameter 5mm),Short bar 9x5Φ

(5pcs of long reinforcement bars,9pcs of short bars,the diameter of bar is 5mm)

50mm panels

Installation of special 75mm and 50mm panels with wooden frame structure

In Australia and New Zealand

Fireproof and insulation panel

ALC panel is composed of many small holes, which are independent and in order. The porosity is nearly 80%. The small holes, filled with air, are not connected and the air inside stays static, so air becomes the major thermal conductivity medium. As the thermal conductivity of air is very low, about 0.026W / (m • K),that ultimately makes the thermal conductivity of the material very low, thus satisfying the purpose of the insulation.

| thickness | thermal resistance | thermal inertia index | transfer thermal resistance | heat transfer coefficient |

| δ(mm) | R(㎡.k/W) | D=ΣRS | R(㎡.k/W) | K(W/㎡.k) |

| 50 | 0.31 | 0.92 | 0.46 | 2.17 |

| 75 | 0.45 | 1.31 | 0.60 | 1.67 |

| 100 | 0.59 | 1.69 | 0.74 | 1.35 |

| 125 | 0.72 | 2.07 | 0.87 | 1.15 |

| 150 | 0.86 | 2.45 | 1.01 | 0.99 |

| 175 | 1.00 | 2.83 | 1.15 | 0.87 |

| 200 | 1.14 | 3.22 | 1.29 | 0.78 |

FIREPROOF AND INSULATION PANELS

ACCESSORY PRODUCTS

Special Function Mortar

Kingway adopts m-tec special mortar production lines and core technology from Germany. Through professional personnel’s continuous research and development, there are six categories (14 kinds) of special function mortar products now, including Masonry (adhesive) mortar,Plaster(skim coating) mortar, putty, waterproof mortar, insulation mortar, interface agent and etc. for Kingway ALC panels and block construction.

The corret using way of our special Masonry mortar(Adhesive Glue) and Plaster mortar(skim coating on surface)of ALC panel:

1.0 kilo of Mortar with 0.15 kg of water(subject to not flow in on the ALC panels),that is the percentage of Mortar with Water is abt 6.5:1,stir well for no agglomeration and no condensate group,3 minutes later,stir once again,you'dd better (finish using)use up all the stired mortars in 3 hours ,maximum in 4 hours,the best ambient temperature is 3 degrees & up,the masonry thickness 3-4 mm,one m2(square meter) of 100mm ALC panel use 6kgs of Plaster mortar and 4kgs of Masonry mortar,the regular sheld life of the Mortars is 3 months,that is the maximum period from the finished goods and your used up all the mortars in site is 3months, it must keep dry placing condition within the transport and warehouse.

Professional joint adhesive(glue) for our AAC panel &block

ITEM | PERFORMANCE INDEX | DETECTION METHODS |

Exterior | Split evenly, without caking | Visual |

Water-holding capacity(mg/cm2) | ≤8 |

|

Mobility(mm) | 120-150 | GB/T2419 |

Compressive strength(MPa) | 5.0-12.0 | GB/T17671 |

Flexural strength(MPa) | ≥2.20 | |

Pressure to cut cement strength(MPa) | ≥1.0 | JC/T547-1994 |

Pressure to cut cement to freeze-thaw resistance strength(MPa) | ≥0.40 | |

Shrinkage(%) | ≤0.30 | JGJ70 |

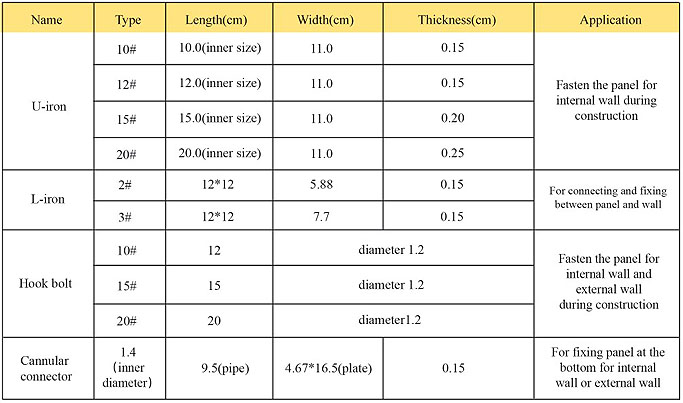

Specialized Accessories

Usage of main accessories

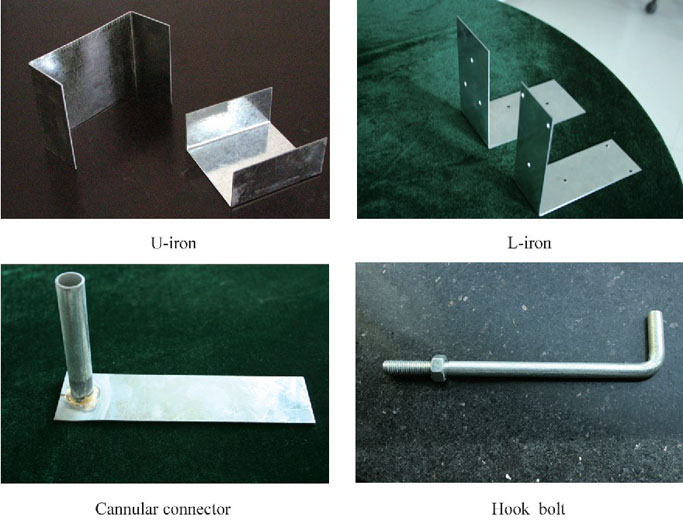

Some Necessary Tools

Packing by plywood pallet and loading in containers

CONSTRUCTION

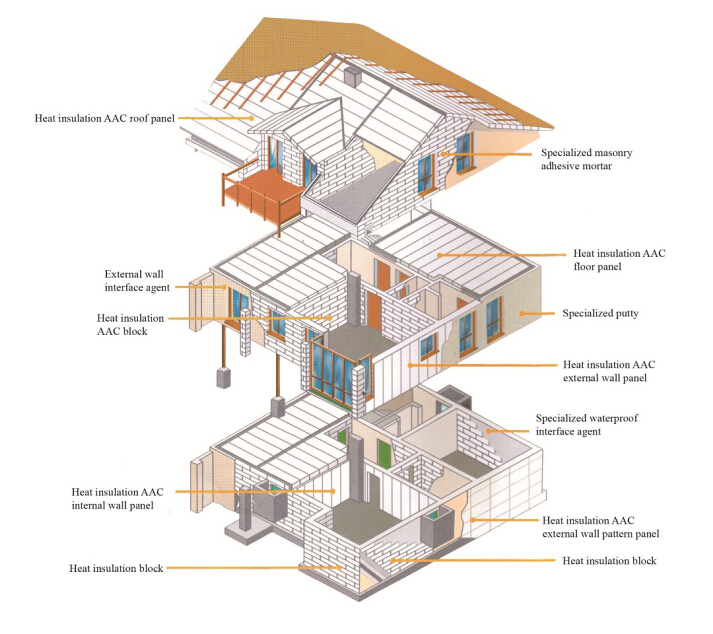

Systematic Solutions

According to the different customers and characteristics of construction, we provide systematic solutions that feature AAC panels of different specifications, performance and supporting auxiliaries. This not only meets the building and decorative requirement, but also makes every part to match perfectly, and the uniform structure of materials will reduce the contraction ratio of heat channel to a minimum.

Installation of ALC Panels

Preparation

1.Check the drawing before construction, and compose on-site. While composing and designing, the width of partition wall should fit the 600mm modulus. If the width can't fit the multiples of 600mm, we should better arrange the rest near the concrete column or the side of wall. It's inadvisable to arrange it near the windows and doors.

2.Clean up the joint part between panels and roofs, floors and walls. Clean the floating ash, sand, soil and so on. All the mortar and concrete which are bulged out over the walls should be cleaned up.

3.According to the drawing, mark the columns, beams, floor which is connected with AAC Panel, and pop the two-side upper and lower line of control by using ink fountain.

Installation and construction

|  | |

4-5 workers form a group. Use hydraulic trolley for transportation. Panels should be kept flat during the transportation. Pulling on the floor or unilateral support is forbidden during transportation. Use special fixture when lifting. Hoisting belt should be flexible nylon tie belt. | Use 1:3 cement mortar on the bottom of the panel to make level, mortar thickness is 10-20mm. | |

|  | |

| While installation, one worker uses a chain hoist to make the panel stand up, other workers stabilize the panel to the corresponding location. | Each panel should be connected to major structure by a special U-Card which is shot on the panels by nail gun. | |

|  | |

| After panel is upright, adjust the verticality by a wadge stuffed on the bottom of the panel. | Groove between panels to bite each other should be close. Pay attention to control the verticality during the installation, and check up carefully after installation. | |

|  | |

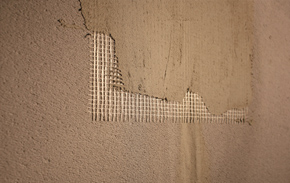

| Gap between panels to be caulked by special mortar, and extra mortar should be pushed out while connecting panels. Then clean up adhesive cracks between panels, and use specialized pointing mortar to fill up gaps and level out. | To avoid cracking on gaps between panels, cover the adhesive gap with a layer of 200mm wide alkali-resistance fibre mesh. |

Remarks

1.If we need to install water and electricity pipes in advance during the construction, slots can be cut in both vertical and horizontal directions on the panels, because there are two layers of steel structures inside the panels. When it is necessary to cut bigger holes in the panels for terminal boxes and distribution boxes, the holes can be slotted in the panels as per demand. After installation, the slots can be filled up smoothly with polymer mortar or gypsum powder. Sizes of holes or dehorns should not exceed 1/3 of the panels. Cut with cutting machines. Slots can only be carved three days after installation.

2.As the wall body is jointed by panels, reinforcement is needed when opening holes. If the width of openings is more than 400mm, auxiliary reinforced structure must be used.

3.When panels are used for wall partition in kitchens and bath rooms, waterproof process must be done according to waterproof design requirement .

4.Light-weight objects such as fittings, hooks and so on can be fixed directly on the panels with drilling nails. Heavy objects about or more than 10kgs such as wash basin, heating unit, water heater, cupboard and air conditioner outside and inside should be hung on the panel wall body using expansion bolts.

5.Windows and doors can be installed with nylon expansion bolts. Bigger windows and doors can be installed with flat steel and angle steel that are fixed by nails. At the top of windows and doors, a dripping line should be made with polymer cement mortar. Window sill should be pasted with cement mortar. There should be slope at window sill outside and window sill board can be installed at window sill inside. The place around between windows and door should be pasted with styrofoam and sealant outside.

6.When panels are connected to other wall body, beams, columns or roof panels, there must be a 10-20mm gap on the top. The gap should be filled with foaming agent or polymer cement. If there is fireproof requirement, the gap should be filled with rock wool.

7.If stone products and decorative metal products are to be hung on the outside walls, auxiliary metal frame should be pre-installed. The metal frame is usually fixed on the beam and column of the building. Under special condition, for example, when the space is too large between beam and column, the strong support parts should be added between beam and column.

8.External panel walls can be pasted with waterproof putty and then painted directly. Internal panel walls can be pasted directly with putty.

Partition work on beam

Installation of panels in part of window and door

As there are two-way steel bars in the panel,we can slot for horizontal,vertical or inclined grooves for electric box and pipeline

Installation of external wall panels

Fixing the panels by welding hook bolt onto the steel structure

From outside,the above part of another end of hook bolt From outside,the below part of another end of hook bolt

external wall panels with steel structure(outside) external wall panels with steel structure(inside)

external wall panels with concrete structure

ENGINEERING PROJECTS

Our Engineerings in Australia

Our Engineerings in Singapore

Our Engineerings in Philippines