RIZHAO HANDING STEEL STRUCTURE TECHNOLOGY CO.,LTD.

The company has 2 heavy steel production lines ,1 box beam production line ,1 intersecting production line and other advanced processing equipments.

Our workshops of steel structures

1.Prefab house of Light Steel Structure with insulated concrete panels

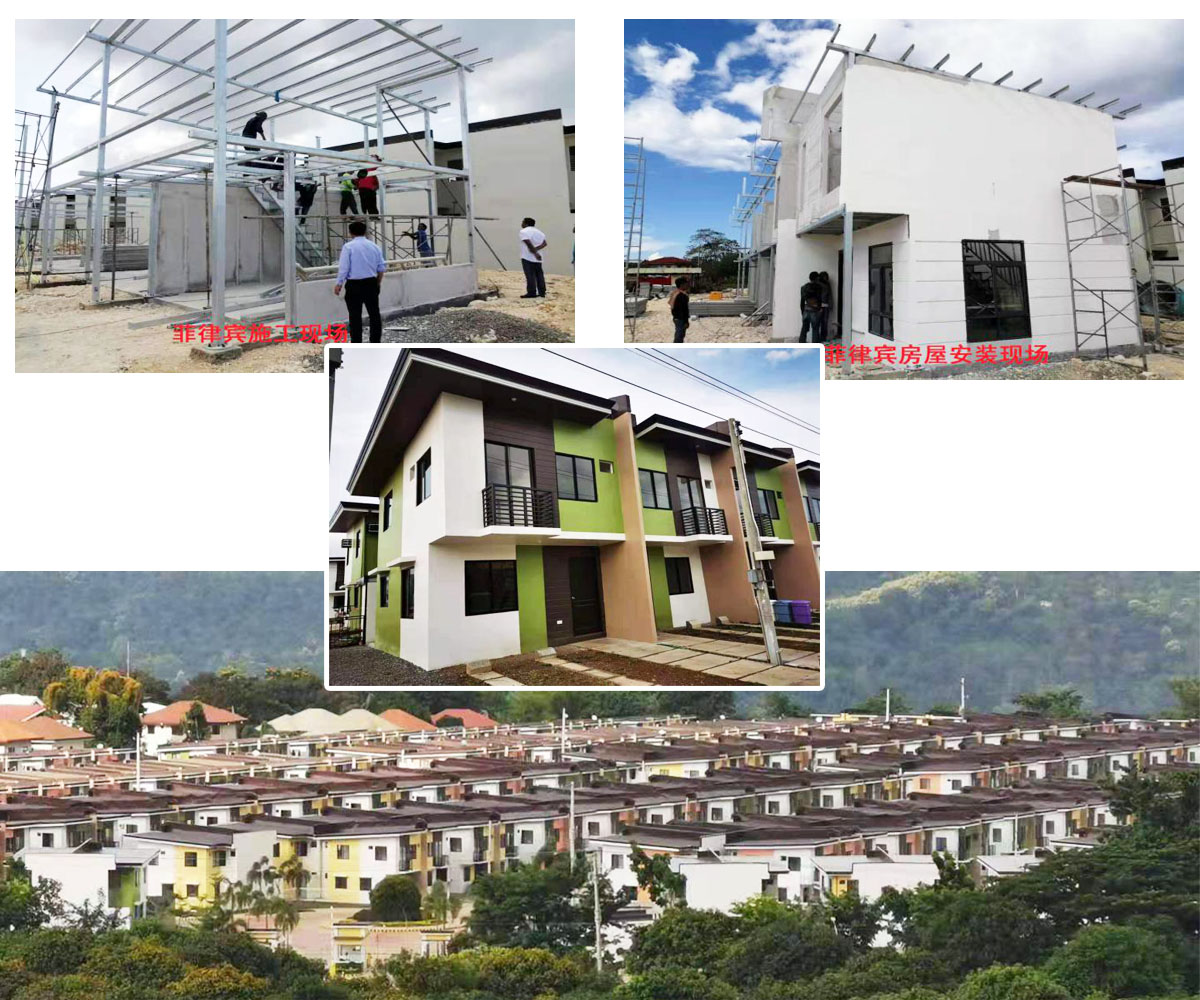

The company closely responds to the national "Belt and Road" strategy, after market research of many years, making full use of domestic excess capacity and resources, it has developped and produced a new type of steel structure housing“Prefab house with Hot galvanized tubes and ALC(AAC) panels”, now the supply of our product exceeds supply,it’s popular in South-east of Asia,it has been highly affirmed by our VIP Philippine cooperator and Philippine government department of housing management.

Attending exhibitions in Southeast Asia

Our VIP cooperator in Philippines visiting our factory

Spanish costomer visiting our workshop

Our workers testing the finished steel structures before delivery

Our finished projects in Philippines

2.Design and processing of large and medium steel structure workshops and workshops

3.Light steel view rooms, houses, villas

Light steel landscape room is our company specially for tourist attractions and leisure houses to build houses, this type of housing modeling changes, heat preservation, earthquake resistance, sound insulation performance is good, easy to install and move, the whole process, energy conservation and environmental protection, is a new type of green building.

4.Containerized mobile rooms

Container mobile rooms are widely used in construction sites, nursing rooms, all kinds of temporary facilities, emergency facilities, etc., with quick installation, excellent combination performance, can be quickly combined installation in place, can be put into use in a short period of time.

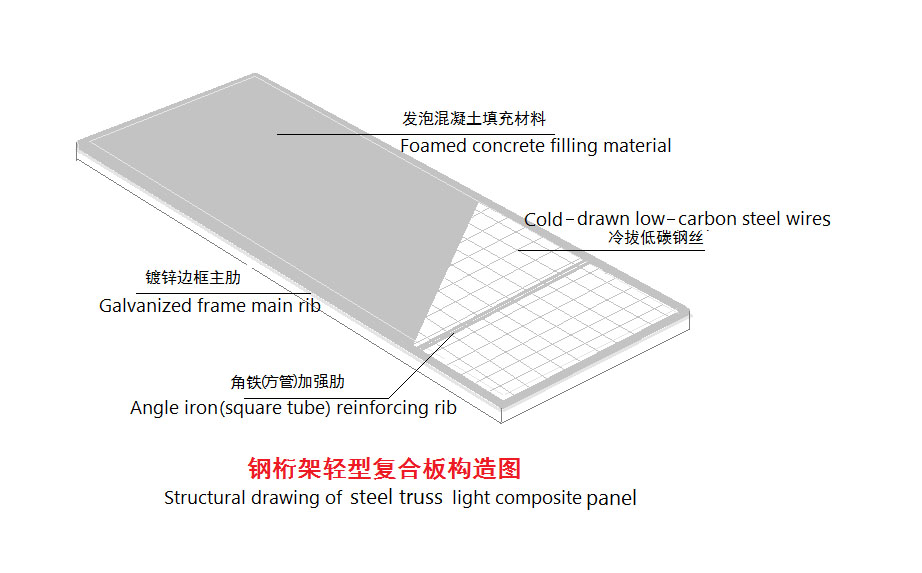

5. STC”Steel truss light composite panel”

Steel truss insulation roof panel, steel skeleton light insulation wall panel, steel truss sound insulation composite floor panel, steel skeleton loft panel, steel truss long span light panel, etc.

STC”Steel truss light composite panel” is a new type of green environmental protection light panel, which has the characteristics of light weight and high strength,composed by around galvanized C-style steel and inside reinforcing bars with light concrete inorganic compound,the original invention concept is making a best load-bearing panel in putting together the steel structure and insulated concrete panel such as ALC(AAC) panel or other concrete panels, but ALC panel is not a load-bearing panel,ALC panel must be matched with steel frame,concrete frame or wooden frame.The new STC panel is invented,designed and produced by our own factory,it can be used as Internal wall panel,External wall panel,Floor and Roof bearing panels etc., combined with the constructions of Steel structure,Concrete structure and other mixed structures etc.

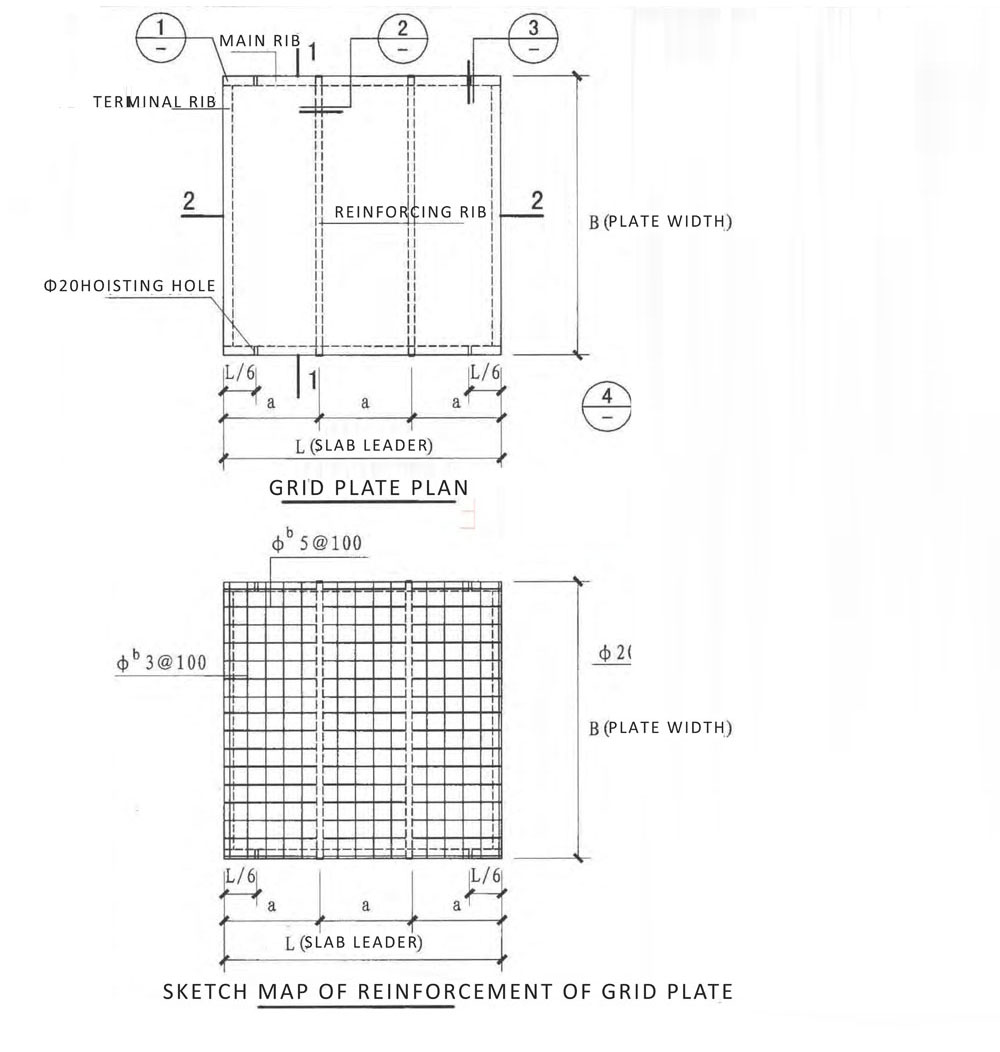

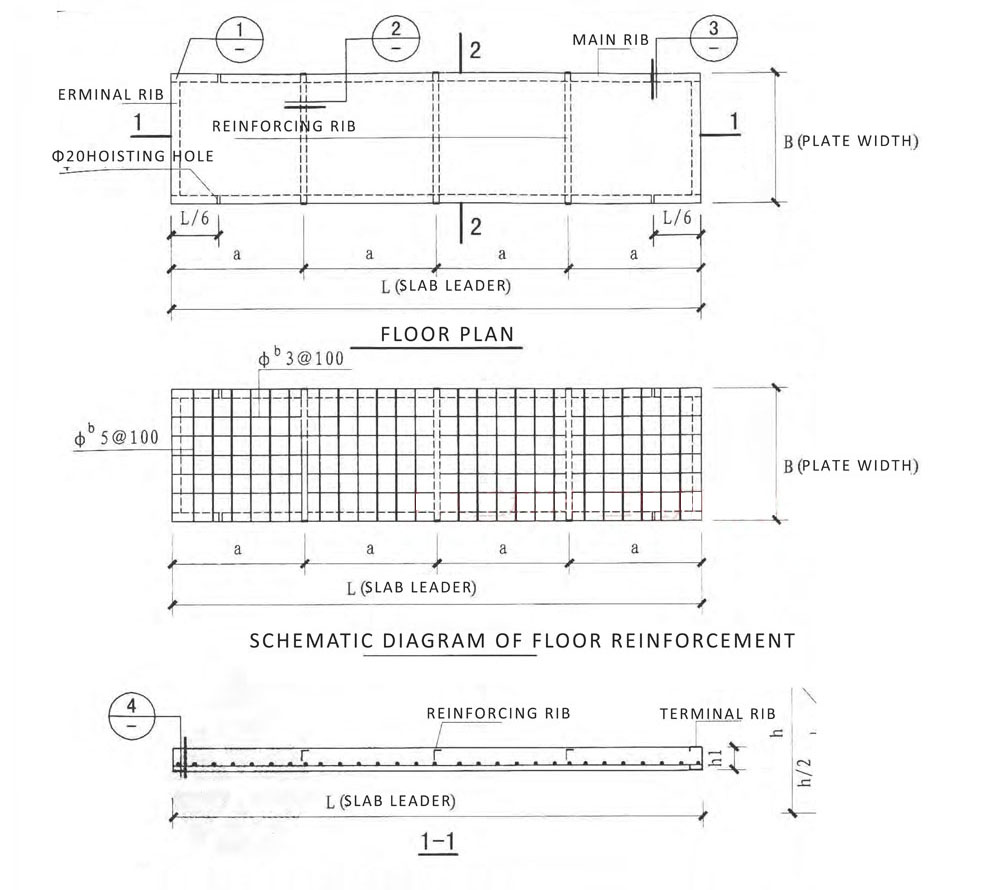

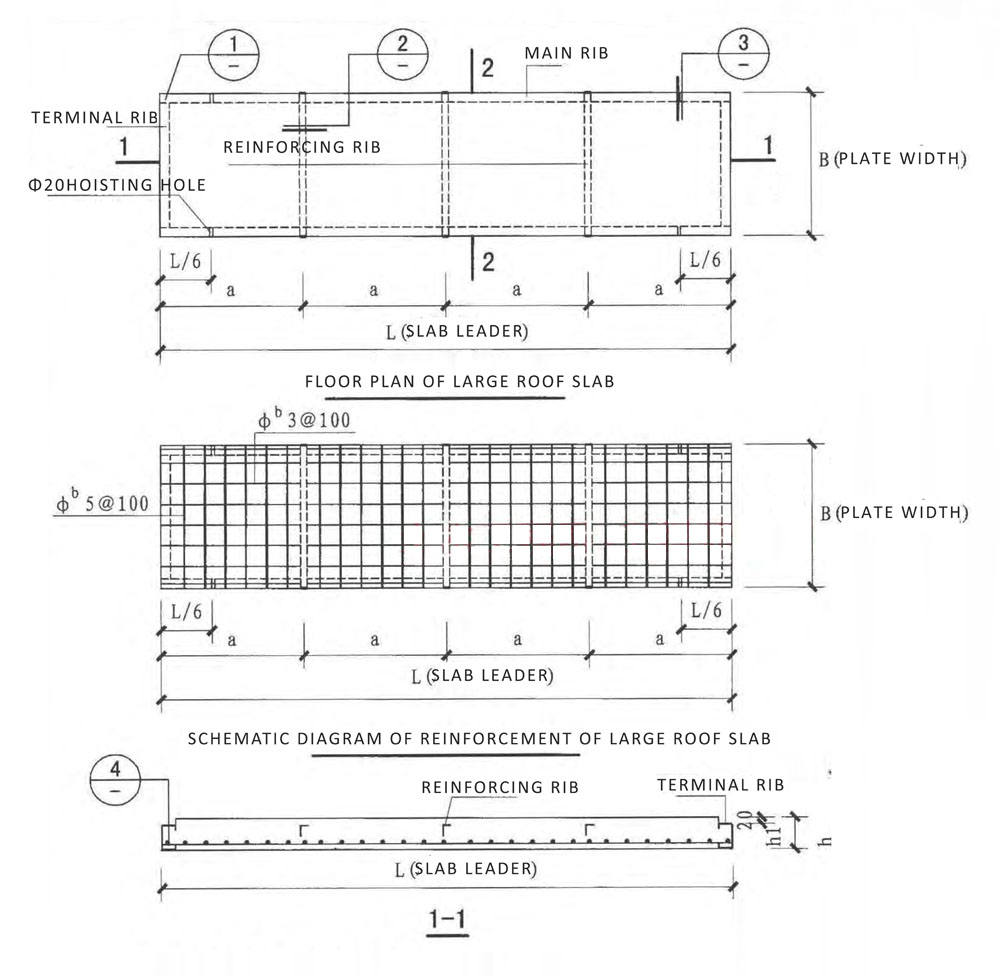

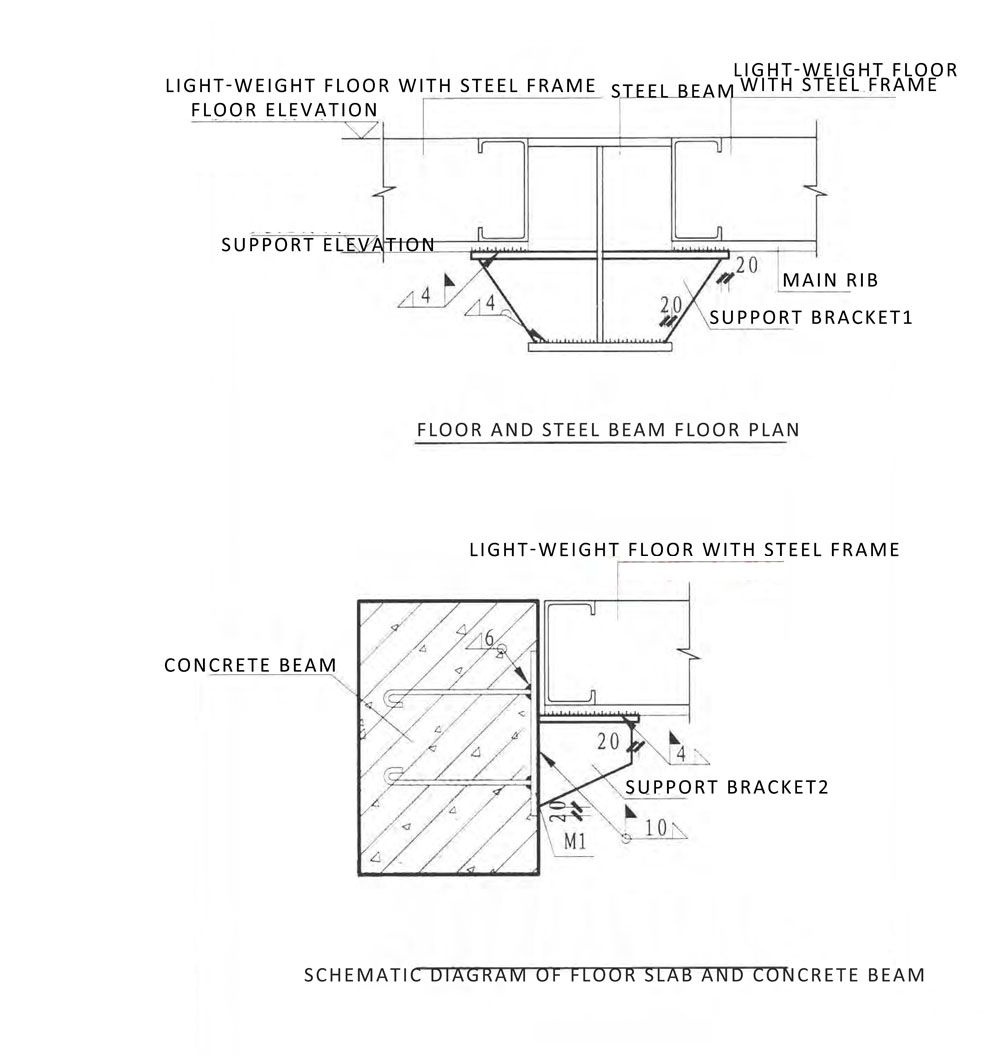

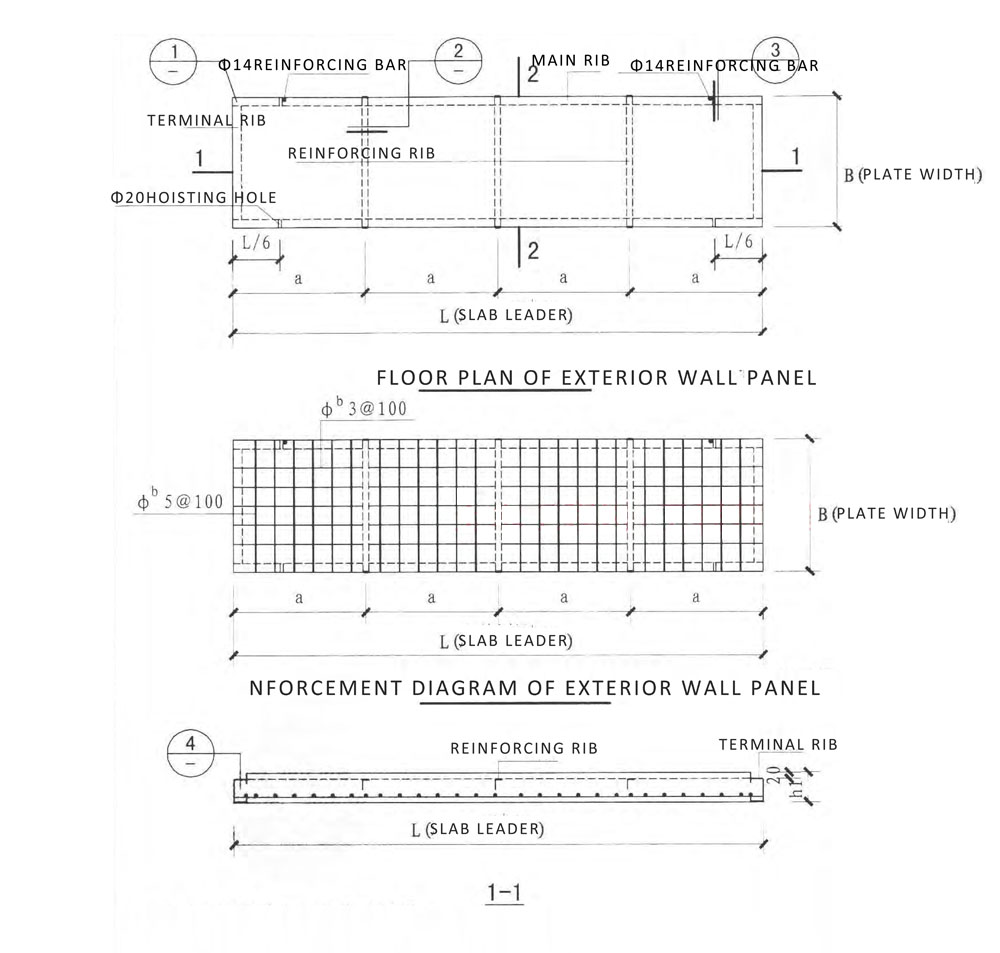

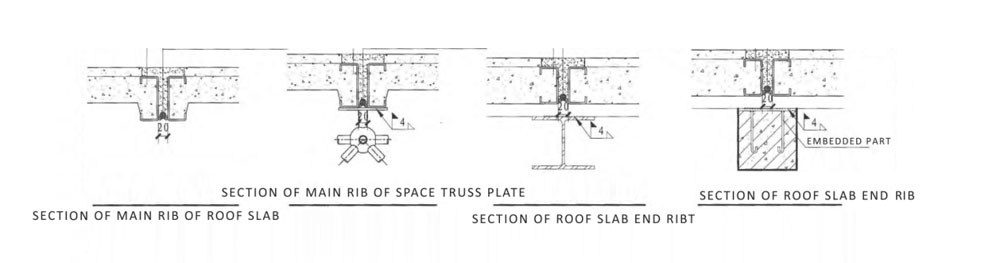

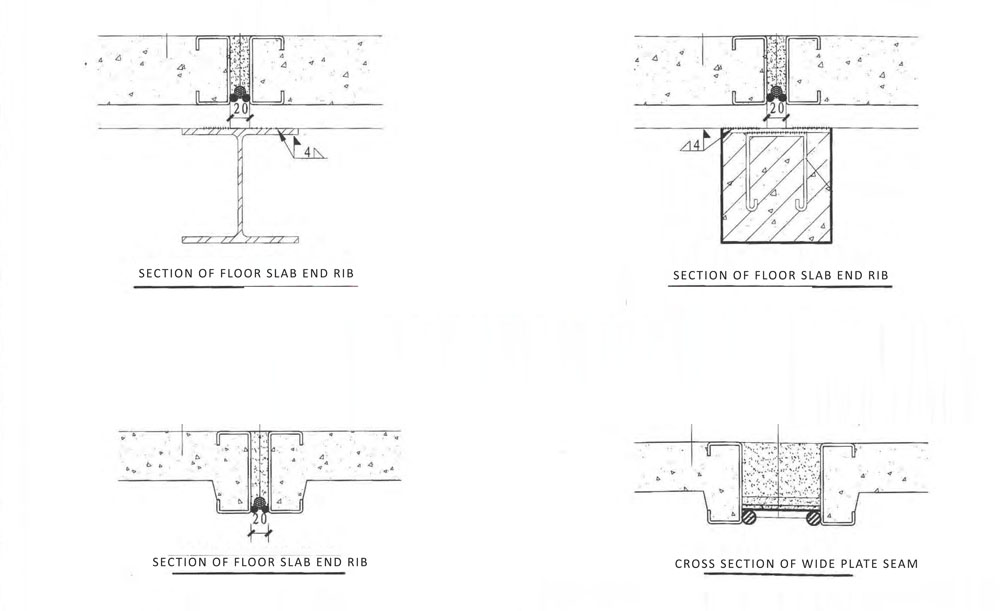

Drawings of inside Reinforcing bars of STC Wall panel,Roof panel,Floor panel.

According to the use of the site is divided into steel truss light floor board, steel truss light wall board, steel truss light roof board; according to the use of construction works are divided into gutter board, mesh board, truss board, trestle board, loft board, etc. reduce the tedious construction process and safety hidden trouble (scaffolding, formwork and formwork support, etc.) of long-span structure, and greatly shorten the construction period.

According to the increase of steel structure house, workshop and so on, the steel truss insulation roof slab is developed by our company. It can solve the common problems such as poor durability and difficult maintenance of roof colored steel tile. It is an ideal substitute for concrete double T-slab.

Performance Characteristics of STC”Steel Truss Light Panel”:

1) Light weight: light weight is mainly concentrated in core material, core material is the core technology developed by our company. it consists of foamed concrete, expanded perlite, high grade ultrafine fiber, anti-cracking active enhancer. the bulk density is 500-700kg/m3, only 1/2-1/3 of the weight of the traditional board

2)High strength: adopt hot-dip galvanized light steel frame, built-in rib reinforcement, cold-drawn low carbon steel wire mesh combination structure to form skeleton, and then add wear-resistant and crack-resistant surface layer, maintain the advantages of high safety of traditional reinforced concrete slab. The design value of allowable applied load ≥1.5 kn/m2(sqm), and the failure load can reach 4 kn/m2.

3) Durability: the main materials are inorganic materials made of foamed cement, the border is hot-dip galvanized anti-rust treatment, strong anti-aging ability, good durability, can effectively resist the erosion of acid, alkali, water vapor, the service life of structural design is 50 years. freeze-thaw cycles for 25 times, with almost no change in volume and strength.

4) Thermal Insulation: the foaming concrete light core material developed by our company, with closed porosity of more than 95%, has a unique microporous structure, which makes it have excellent thermal insulation performance, low thermal conductivity, and the heat transfer coefficient of the whole plate is 0.5-0.8 w/m2k, which can select different thickness and thermal conductivity insulation materials according to the energy saving design requirements of different regions, and meet the heat transfer coefficient requirements of energy saving regulations in various regions.

5) Wind and snow resistance: according to different types of plate type and design load, resistance to negative wind pressure, not afraid of snow, avoid many defects and common 6) Fire insulation: steel truss light composite board material is mainly a grade non-combustible material, under the standard load, the fire resistance limit is not less than 2 hours, does not burst during combustion, does not release any toxic gas, no smell, no smoke, not only has excellent fire resistance, but also meets the environmental protection requirements of modern buildings. the back temperature of the plate is only 50℃ when the bottom 900 is baked at high temperature in the fire proof experiment, indicating excellent thermal insulation.

7)Earthquake resistance: light plate is conducive to building earthquake resistance, plate and main structure and plate and plate between the use of welding, integrity is good, can meet the 8 degree seismic fortification intensity requirements. And when the earthquake occurs, the secondary damage caused by the plate is small.

8)Sound insulation: because of the high porosity of the microporous structure inside the plate core, the average sound insulation is not less than 40 db, with excellent sound insulation effect.

9)Explosion relief: steel truss light composite plate special structure, can be used as a building anti-explosion pressure plate, when the explosion occurs, the plate core material will instantly absorb and release explosion energy to release the pressure quickly, so that the main structure and roof plate steel skeleton will not be seriously damaged, will not produce secondary injury.

10)Green environmental protection: steel truss light composite board materials do not contain any formaldehyde, benzene, ammonia and tvoc and other harmful gases and radioactive materials, in the production process without waste water, exhaust emissions, do not use paint, adhesive and other materials, belong to green environmental protection health products flexible and convenient to use, plate specifications according to the characteristics of the building tailor-made, no need to lay purlins, the board can open holes, install lighting cover, roof pipes, fans.

11)Simple Maintenance: normal use without special maintenance, use low cost. Local damage can be repaired directly on the roof. If necessary, it can also be replaced by veneer without affecting the overall structure.

12)Economy: the use of steel truss light composite board can obviously save the amount of steel used in the house, reduce the steel structure support system, easy and fast installation, shorten the construction period, save manpower and material resources, and the comprehensive economic benefits are obvious.

13)Steel structure assembly combination: combined with the use of steel structure assembly housing developed by our company, the construction period is greatly shortened, and all the main components are customized and processed in the factory, and the social benefits are obvious.

Our representative in Singapore,Malaysia,Thailand and Indonesia:

Mr. Michael Yeo

Email address: yeomichael53@gmail.com

Telephone number +65 96345693

can be contacted via WhatsApp @ yeomichael