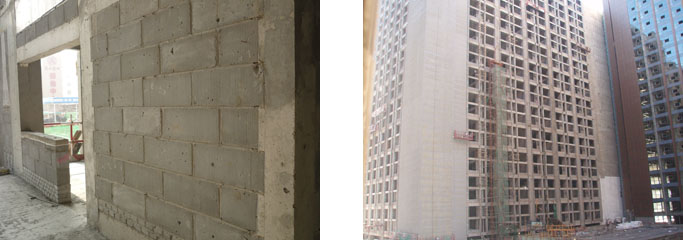

AAC (ALC) Block

Autoclaved Aerated Concrete (AAC) has been used all over the world for decades, firstly produced in terms of industrial means in Sweden in 1923. It is a unique building concept, available in today's market with innumerable building advantages.

AAC is lightweight concrete that is produced under special circumstances, by adding aluminium paste which creates a porous shape into the mixture of cement, finely grounded quartz sand or flyash, water and limestone. AAC is very firm and the most durable construction material that provides heat insulation by its porous texture, security against earthquakes through its lightweight structure,and safety against fire by its non-flammable quality (Fire Class A1).

This very precise material AAC that is easily processed by not harming the environment at all has the characteristics of being produced very accurately in terms of dimensions.

Furthermore, it enables you to save money in transportation, workmanship, use of steel and cement. That's why AAC is largely used in residential, industrial, commercial, social and public construction projects(concrete structures and steel structures).

AAC building products can be used for all applications including every type of masonry walls, roofs and floors. AAC is largly preferred especially in many developed countries such as all EU countries, USA, Japan, Russia,Australia and all Gulf countries and Kingdom of Saudi Arabia,and most developing countries.

Main advantages of AAC concretes:

Insulating

The excellent insulation properties of AAC mean that a pleasant interior environment can be achieved and maintained. This property also reduces the initial investment and heating/cooling expenses.

Lightweight

AAC is a lightweight product compared to other solid building materials,about one-forth 1/4th of normal concrete block and one-third 1/3th of clay brick. Light weight promotes lower life & injury risk during earthquakes. However, despite millions of tiny air-filled pores, it is still solid. The low weight has advantages when transporting and working with the product as well as for structural design where savings in mass and weight make much more affordable structures possible. This means lighter supporting structures and more compact foundations in both residential and commercial construction projects.

Precise

The patented manufacturing process ensures that AAC is always produced true to size as they leave the factory. This results in less on-site trimming and reduces the quantities of mortar and finishing materials being required. It can be sawn, drilled , nailed and machined using normal wood working tools.

Fireproof

AAC provides maximum fire safety. It is totally inorganic and incombustible, and can be used for all fire-resistant and vision walls.

Ecologic

AAC products are produced with minimum energy, without using agricultural soil. They are non-toxic and do not pollute the environment during production or construction stages.

Multi-purpose

AAC can be used for all applications including both load and non load-bearing walls, roofs and floors. It can easily be shaped for ornamental and functional architectural details.

|  |

| Insulating and Sound-absorbing | Soundproofing |

|  |

| Wall Partition | Internal Wall |

|  |

| Systematic solution | House Sample |

Kingway AAC Blocks

Kingway is located in Qingdao city,Shandong province,north of China,it has manufactured the lightweight building units of reinforced(AAC Panel) and non-reinforced concrete(AAC Block) with the most advanced autoclaves using basic raw materials such as quartz sand or flyash, cement, and lime,in accordance with GB11968-2006 and GB15762-2008,Chinese national standards.

AAC block is made mainly silica sand(or flyash),cement,lime,and water plus aluminium powder as a foaming agent to the concrete in a mould, with a complete technological process such as high temperature,high pressure and steam curing etc, it's a new type of light,environmental and prorous building materials.

Specifications

| L(length) | 600mm |

B (breadth) | 100mm,120mm,125mm,150mm,200mm,250mm,300mm |

H(height) | 200mm,240mm,250mm,300mm,400mm |

Technical data (Performance index)

| Bulk density grade | B04 | B05 | B06 | B07 | ||

Normal dry | Prime (A)≤ | 400 | 500 | 600 | 700 | |

Acceptable (B)≤ | 425 | 525 | 625 | 725 | ||

Strength grade | Prime (A) | A2.5 | A3.5 | A5.0 | A5.5 | |

Acceptable (B) | A2.0 | A2.5 | A3.5 | A4.0 | ||

Drying contraction | Standard method | 0.5 | 0.5 | 0.5 | 0.5 | |

Rapid method | 0.8 | 0.8 | 0.8 | 0.8 | ||

Frost resistance | Weight less %≤ | 5 | 5 | 5 | 4 | |

Strength (Mpa)≥ | Prime (A) | 1.60 | 2.8 | 4.0 | 4.5 | |

Acceptable (B) | 2 | 2.8 | 3.2 | |||

Thermal conductivity | Dry (w/m.k) | 0.11 | 0.13 | 0.15 | 0.16 | |

Professional Joint Adhesive(Glue)

Technical data (Performance index)

| ITEM | PERFORMANCE INDEX | DETECTION METHODS |

Exterior | Split evenly, without caking | Visual |

Water-holding capacity | ≤8 |

|

Mobility (mm) | 120-150 | GB/T2419 |

Compressive strength | 5.0-12.0 | GB/T17671 |

Flexural strength(MPa) | ≥2.20 | |

Pressure to cut cement strength(MPa) | ≥1.0 | JC/T547-1994 |

Pressure to cut cement to freeze-thaw resistance strength(MPa) | ≥0.40 | |

Shrinkage(%) | ≤0.30 | JGJ70 |

How to use the adhesive(glue)?

The corret use way of our special adhesive (glue) of AAC block :

One kilo of glue with 0.20-0.30 kg of water(subject to not flow in on the AAC blocks),stir well for no agglomeration and no condensate group,3 minutes later,stir once again,you'dd better (finish using)use up all the glue in 3 hours ,maximum in 4 hours,the best ambient temperature is Zero degree & up,the masonry thickness 3-4 mm(for other kind of normal glue which price may be lower ,the minimum masonry thickness is 10mm),one m3(cbm) of AAC block use 27-30kgs of the special Glue,the storage period of the Glue is maximum 6 months.

Construction Technology

The process flow chart is suitable for the construction of industrial and civil building non-load-bearing walls, non-bearing and thermal insulation energy-saving external wall, industrial and civil building fire partition wall,which are used of AAC sand (or flyash)blocks

Prepare the AAC blocks before construction

1)After the blocks are put in job site,they should be put in batches and specifications in order and sticked with label.

2)When stock piled,the bottom should be put up but not touch the floor directly,pls pay attention to avoiding water in order to become damp,the height of stock piled is not suitable to exceed 2 meters.

3)Before fixing the block,the necessary tools under construction such as spatula,rubber mallet,level ruler,hand saw,cutting machine,measuring reel,angle steel ruler,steel rule plate,sanding plate,electric mixer and so on.

Construction of AAC blocks

1.Setting-out before construction,start the masonry after setting out,before the external masonry,while setting out, you should leave a empty space of 5cm in the concrete part for making the insulation layer on the thermal (cold-hot) bridge.

2.The precise sizes of AAC blocks can ensure to use the drying method of thin adhesive.For making sure the adhesive to glue well,the adhesive should be mixed by electric mixer.The ratio of clear water and dry adhesive is 1:5.The mixture should be used up within 4 hours.It must be remixed after more than 30 minutes.

3.The ground should be watered and leveled by cement mortar before fixing the first layer of block.The first layer of blocks should be glued with adhesive for fixing strongly the bottom to the ground,the thickness of adhesive is about 2-3mm.The second layer of blocks should be fixed in 3-5miniutes after the concretion of the bottom mortar,this is the key to ensure the strength and smooth of the whole wall.

4.If the surface of next layer of blocks is not smooth,it can be corrected by matting plate(dull polish),then cleaning the floating dust.The fixed blocks should not be moved and knocked on freely.If any blocks need to be corrected,it should be fixed after smearing the adhesive again.The levelling instrument and rubber mallet should be used to correct the planeness and verticality of the blocks under construction.

5.Corner parts should be fixed at the same time with other parts.The blocks can be cut by special desktop cutting machine.There are two connecting methods between wall and concrete components:L-shape support part(L type member) and tie bar.The new way of L-shape support part takes the place of that of tie bar,In this way,it saves much time and makes higher bonding strength and higher deformation resistance.One side of L-shape support part connects concrete column and wall with shooting pin,and the other side of L-shape support part connects the block level masonry surface with 3-inch nails,in this way,the wall and concrete column or foundation wall connect into the whole.One piece of L-shape support part should be setted for every 2 layers of block.The blocks should be lapped in fissure of displacement,,the slapped length should be more than 1/3 of the fixed blocks and more than 10cm so as to guarantee there is no the phenomenon of straight joint.

6.The two sides of door and window opening need to bury solider concrete blocks from top-mid-bottom for fixing the frame of door and windows.At the top of the opening ,there should be lintel to guarantee the integration of the wall and avoid thermal(cold-hot) bridge.When reinforced concrete lintels are used under construction,The lintel should be narrower 5-10cm than two faces of wall to leave the the space to plaster and make level.In a gap of construction,it should make a oblique cha(section) which level projected length must be more than 2/3 of it's height,it should clean the floating dust and debris of the slant rubbings and spead newly the adhesive before the following new construction,that ensures the solid caking(cohesion) of blocks.

7.The construction method with masonry with clear is helpful to keep the wall clean,to save material in collecting the extruded adhesive for using again .Keeping the thickness 2-3mm of mortar joint is the basic requirement of thin layer construction method.Thin layer construction method not only saves building materials, reduces the shrinkage of the ash seam ,improves the integrity of the wall, avoides the mortar effect ability on the impervious wall, and improves the crack resistance capacity of the wall. After the completion of the wall masonry, the wall and the structure will have some deformation, it should leave gaps of 10-20mm at the top of wall ,then after 2 weeks fill the gaps with PE bar and foaming agent,it can effectively avoid the wall cracks caused by structural deformation.

8.After completion of wall masonry,it still need to check its planeness and verticality, , repair the truncation and off angle of wall with patching materials, correct the deviation parts with steel ruler,mill plate and matting plates, making the revised deviation within the allowable range, but when the wall is higher more than 6 meters,it should set the structural concrete column and steel column

Notes:

1.While the length of the wall is less than 6meters,the slot between wall and pillar should be avoided.The space should be filled fully with adhesive between block and pillar.While the block and short-leg shear wall or structure column are at the same level,tie bar are proposed to

use. AAC block using the slotting method

2. Due to the big difficulty of operation in the use of plastic stick, it is difficult to guarantee quality, proposed to abolish the PVC plastic rods, and take use of PU foam

9.The construction of insulating blocks at the concrete part can be carried out after the completion of wall masonry,the insulating blocks should be glued by exclusive adhesive,the thickness of adhesive 2-3mm.The position under 24mtrs should be setted support measures in every two layers. The position above 24 mtrs,in addition to setting support measures in each layer,it should also increase the mechanical fixing measures,fixed by the special anchor which is not less than 2 pieces in every square metre, and increased properly in the corner position.

How to make the constructional(structural) column

Constructional column of reinforced concrete

1. If the length of wall is more than 6meters or more than 2times of the wall's height,it should set the constructional column of reinforced concrete.

2. AAC wall can be built into the straight Cha or horse bud Cha, connecting wall and structure column can be used L shape support part(L-shaped iron piece) or steel tie bar.

3. AAC wall has strong rigidity, when the reinforced concrete structural column is used,it should use the rachel anchor bolt to fix the template, tap tap, to avoid damage to the already masonry wall and ,to effect the later use of the wall.

4. When the concrete has a certain strength, without affecting the strength,it should make the surface of the concrete column reasonably smooth, so as not to affect the later decoration by putty on the wall surface, and increase the cost.

Detailed introductions:

1).when the length of wall is more than 6meters or more than 2 times of the wall height,the reinforced concrete column should be set.The thickness of wall is 200mm/250mm,the size of the reinforced column should be 80mm*80mm.When the the thickness of wall is 150mm, the column should be 50mm*70mm.

2).Installation tools for reinforced concrete column: Cutting saw, line sinkers, ruler, electric drill, electric welding machine, pump, spray can, small leather buckets, brushes.

3). Installation materials :antirust paint,thinner,L shape support part(L-shaped iron piece),steel plate(150x150mm), electrodes,8# expansion bolt and sleeve plate

4).The installation of steel column:1)The reinforced column,floor and sleeve plate should be antirust treated 2)The steel column should be cut according to the height of wall.3)Expansion bolts should be installed by drilling and floor plate should be welded according to the wall center line. 4)Reinforced column should be welded and sleeve plate should be installed. 5) Verticality measured by guiding rule refer to the following format 1.2. 6)The top of reinforced column should be fixed and expansion bolt should be installed by drilling and then the L shape support part should be welded to reinforced column and expansion bolt. 7)Antirust treatment:the welded joint point and expansion bolt should be antirust treated.

The position of structural column and allowable

deviation of vertical moderate

| No. | Items | Allowable deviation (mm) | Inspection method | ||

1 | central position of column | 10 | Inspection with theodolite or sinker and ruler, or with other measuring instrument | ||

2 | Dislocation in interlayer | 8 | |||

3 | verticality | Each floor | ≤3m | 5 | Inspection with 2m brace |

>3m | 8 | ||||

Full height | ≤10m | 10 | Inspection with theodolite or sinker and ruler, or with other measuring instrument | ||

5).Steel column details see above; the connection of steel column and reinforced concrete beam, plate is fixed by 8 bolts anchoring connection (L10J125 autoclaved aerated concrete block construction) to ensure reliable connection structure column and structure.

Laying Electric box, pipeline

1.The laying work of electric line box can be carried out after that the wall masonry has been completed and the wall is reached a certain intensity. First pop-up the positions on the wall for pipeline,box,slotting and carved hole according to design position,then slot line by handing electric cutter and manual slot machine.The depth of slot:Vertical seam shall not be greater than 1/3 of wall thickness.Horizontal seam thickness shall not be greater than 1/4 of wall thickness.The size of box hole should be a little larger than outside size of the box.

2.After the box hole is finished, the hole should be cleaned,the hole should be wet by water,later bury terminal box and switch box by M10 polymer cement mortar.

3.The pipeline slot should be filled smoothly by polymer cement mortar,then paste the fiberglass mesh cloth wider than 100mm along the slot.

The used main equipment of the method

1)Mechanical: construction hoist, hoist, electric mixer, bench cutting machine etc..

2)Tools: spatula, level, Shouban saws, cutting machine, tape measure, steel ruler, steel template, matte board, electric mixer, brush, leather, nylon line pole, a red pencil, crowbar, hod, hammer, chisel engraved.

Main Accessories

Engineering Cases