BRANCH FACTORY OF CEMENT FIBRE BOARD

The factory covers 50,000 square metres,specializing in the research,manufacture and sale of cement fiber board and fiber reinforced calcium silicate board.It has carried out lateral technical cooperation with many universities,and imported full set of production equipment.It is devoted to popularizing green and environmental protection products and is equipped with six production lines of cement fiber and calcium silicate board,and two units of 7000 tons presses as well as autoclave etc. equipments.The annual production capacity of various boards is 18 million square meters(m2/sq.mt).With quite high technical content,it’s listed as the new product of scientific and technological development of Shandong Province and passed the inspection of the Test Center of the National Building Materials,the Inspection Center of the National Concrete and Cement Product Quality,the Supervision and Inspection Center of the National Fire-Proof Building Material Quality,the Test Center of the National Supervision and Inspection for Building Material Industrial Radioactivity and Harmful Substances.

1.Brief introduction and specification of cement board:

Cement fiber board, also known as fiber cement board, is a new type of building material, which is made of siliceous, calcium material as main raw material, adding plant fiber, pulping, plagiarizing, pressing and curing. The standard specification of length and width of fiber cement board is 2400*1200mm and 2440*1220mm, with thickness from 4mm to 100mm.

1)Ultra thin board:Thickness of 4.0mm,4.50mm,5.0mm,used as ceiling board or face board of EPS sandwitch panel and other composite panels.

2)Regular board: Thickness of 6mm,8mm,10mm,12mm,used as wall panels or decoration panels.

3)Thick board(Floor slab):Thickness of 15mm, 20mm, 25mm, 30mm , can be used as loft steel structure floor board, attic board, exterior wall insulation board, wall guard board, indoor (bathroom) partition, sound absorption ceiling, curtain wall liner, composite wall panel, outside billboard, metallurgy, electric furnace insulation board, electrical distribution cabinet, transformer partition, etc.

4)Super thick board:Thickness more than 30mm, producing according to the special needs of customers.

2. Cement floor slab interpretation:

Cement floor slab is the latest product, which is a replacement product developed and produced by using the latest formula and production technology on the basis of high density fiber cement floor slab.

3.Floor slab market prospect

With more and more stories which height requires 5-6 meters, the continuous rise of freely divided space, we can easily make our own jump layer by using light steel structure and attic floor, one floor changed to two floors, so that the original space is doubled. It can be widely used in floor liner, steel structure and wooden structure floor, replacing plywood and OSB board, and it is a high-end plate in the field of loft plate (floor) in domestic and international market at present.

4.Advantages of floor slabs

The floor slab is a new type of floor developed by using the latest auxiliary materials and the latest formula on the basis of attic board and partition board, which is the replacement product of high density fiber cement floor slab in China at present, and solves the defects such as easy bending and deformation, easy water absorption and expansion, easy delamination and so on. 1) higher strength 2) lower wet rise rate 3) stronger impact resistance 4) higher bearing capacity 5) more environmental protection and safer.

Floor board application range 1) steel structure partition 2) loft attic 3,)warehouse partition 4) factory partition 5) compound building 6) booth 7) floor 8)staircase 9) mobile room

Compared with traditional materials, the main advantages of loft pavilion floor are as follows:

1)the density is high and the strength is high, and the load bearing per square meter is 2 tons.

2)Compared with the prefabricated floor, the weight of the prefabricated floor is lighter, the load of the building is reduced

3)Less thickness, generally 1200 × 2400 × 25mm saves the use space

4)Fire and waterproof,a new type of floor material belonging to A1 grade

noncombustible floor material

5)Low thermal conductivity, the heat preservation and heat insulation effect is good,

6)The sound insulation effect is especially good,

7)The construction is simple and quick, the comprehensive cost is low, and the construction waste is less

8)The service life is generally more than 70 years.

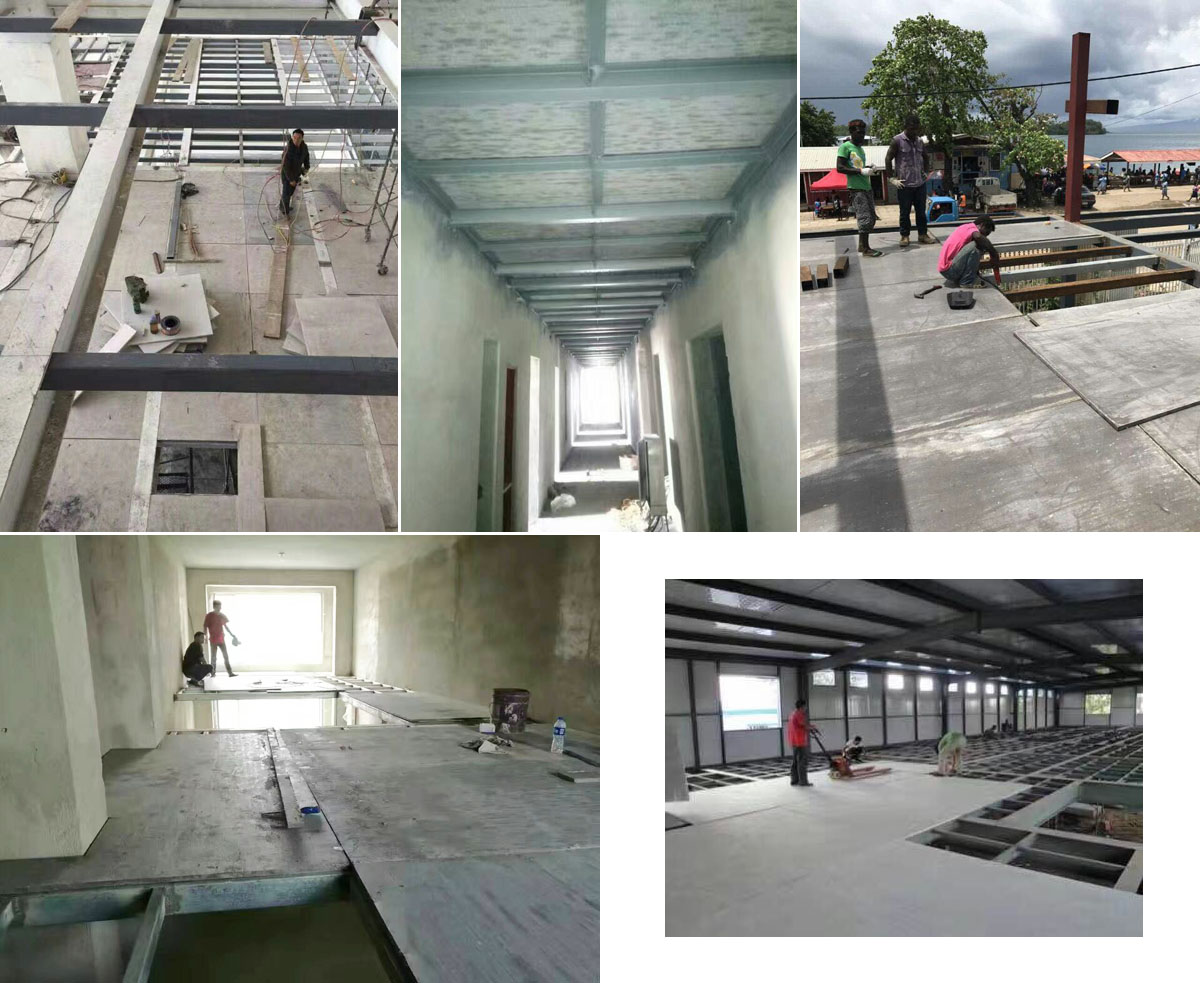

5.Customer visit field

6.Pallet packing and loading in container

At present, the LOFT attic board has been widely used in many projects, in the Bak House of Beijing, the International Center of Dacheng, Rongfeng 2008, the top-show Qingxi Villa, the Longwan Villa, the Zhongyuan Olympic Park, the green villa, the top-ground brilliant international, the Xinxin commercial center, the beautiful and refined area, The Oak Bay Community, the Beijing West Station, the Central Television, the Olympic Bird's Nest and other projects have been used.

7.The relationship between floor slab thickness and steel beam spacing floor plate thickness and steel structure spacing:

20mm floor slab: steel beam spacing: 600*600

25mm floor plate: steel beam spacing 600*600mm or 600*800mm

30mm floor plate: steel beam spacing: 600*1200mm

Note: the specific model size of steel beam depends on the actual area of the building.

The standard surface of floor plate is level and smooth, no warping, no bubble, crack and so on, and the edge is uniform, unbent and delamination

8.Recommended steel beams for floor slabs

1)The span is less than 8m: 15 H section steel of main beam, 10 U-stell of secondary beam, 100mm angle steel of second beam.

2) The distance between the beams refers to the distance from the outer edge of the side beam to the center of the inner beam,and from the center of the inner beam to the center of the inner beam.

3) No embedded parts,fixed by expansion bolts.

4) The upper and lower beam structure can be used in the abundant space, and the plane structure can be used in the lack of space.

9.Welding requirements for steel structures

1)At least three sides of welding, the top surface can not be welded.

2)Weld strength and welding quality must meet the requirements of GB/T5185-1985 and GB/T985-1988 standards.

3) If the edge of the Kingway cement floor slab is in a suspended position, the secondary beam should be added.

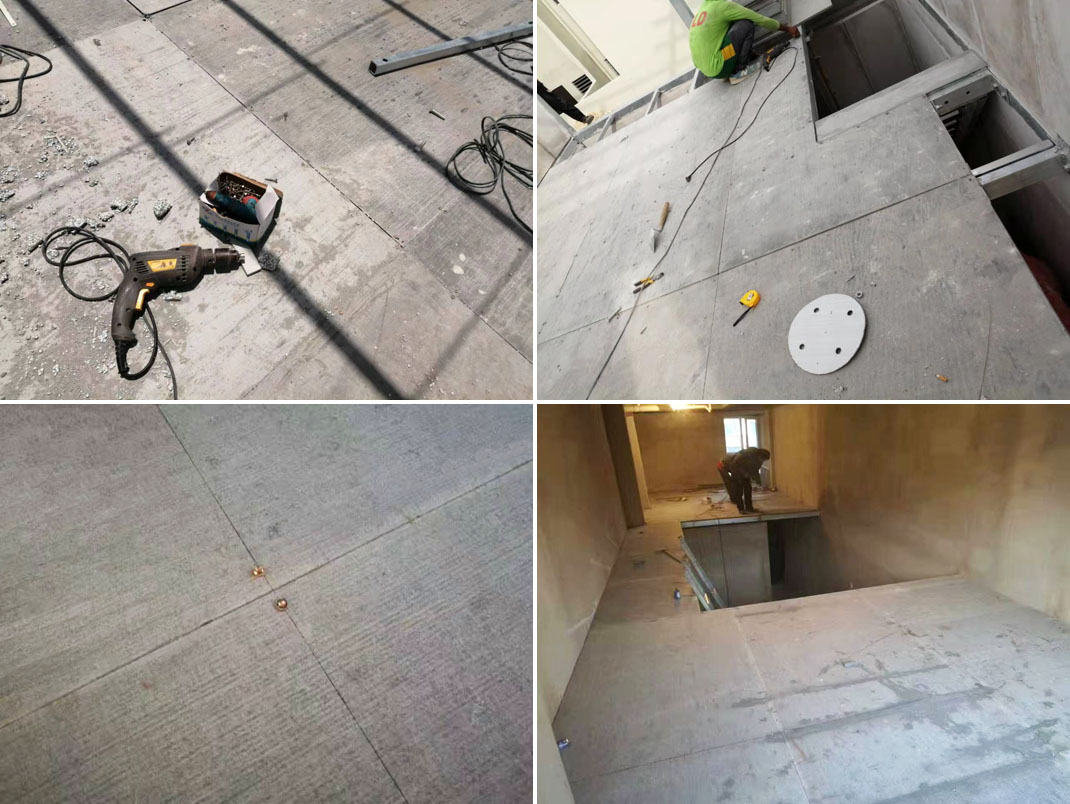

10.Installation of floor slab

1)Before laying the board, the top weld must be polished, and the welding spatter must be removed.

2)The longitudinal direction of the slab should be parallel to the main beam.

3)No edge of the slab shall be suspended.

4) There should be a gap of 3-5mm between the slab and the slab.

5)The joint between the slab and the slab should be located in the center of the beam.

11.The nailing requirement of floor slab

1) The length of self-attacking nail should be 55-60 mm.

2)Drilling first and then nailing, the nail hole should be larger than the diameter of the nail.

3) Start with the nail in the center of the slab, then punch it out, and finally hit the edge nail.

4)The nailing position of the side nail should be about 20mm from the edge of the slab.

5) The nail distance is 300-600 mm.

6)Do not nail on one side of the wall.

12.Treatment of floor slab joints

1)3-5mm gap must be reserved between slabs and slab with wall during paving(it can be no gap with wooden floor).

2)The joint can be filled with silicone sealant or mortar.

13.The follow-up treatment of floor slab project

1)Wood floor can be laid, aluminum foil cushion or unidirectional breathing paper should be laid under wood floor, and the nail head should not stand out.

2)You can do another layer of concrete floor,then lay a variety of floor tiles.

3)Ground heating can be laid.

14.The selection of floor slabs:

1)Slab thickness can generally select from 20-30mm high density thick plate (according to the load-bearing requirements).

2)The selection of the support skeleton:the specification of the main beam should be calculated and designed by the engineer according to the span,at the same time, considering the load-bearing strength of the original structure wall, the secondary beam adopts the square pipe (50*50*3mm) and the fixing screw is M5.5 * 38mm hexagonal drill tail screw.

3)Followings are 3 installation schematic diagrams

(3个图纸)

15.Construction cases in China and Overseas